How Important Are Forklift Check Sheets?

A forklift daily checklist is the difference between ensuring a safe vehicle and causing an incident. Even if it was in excellent working condition the previous day, anything could have happened overnight. So, you must question the vehicle’s mechanisms before each use and partake in forklift check sheets for the ultimate safety.

How Important Are Forklift Check Sheets?

Ultimately, they check whether the forklift is in safe working order, and can be used for liability protection if an incident occurs despite its use being approved.

It may seem like a hindrance each morning, but they can protect you against:

- Further damage

- Costly repairs

- Accidents and injury

- Loss of productivity

- Maintenance

How Often Should I Check My Forklift?

By law, you must have your forklifts inspected every six to twelve months. They do not mandate the use of daily checklists, but it’s good practice to check your forklift before each use.

There are at three forklift safety regulations you must follow:

- Health and Safety at Work Act 1974

- Provision and Use of Work Equipment Regulations 1998 (PUWER)

- Lifting Operations and Lifting Equipment Regulations 1998 (LOLER)

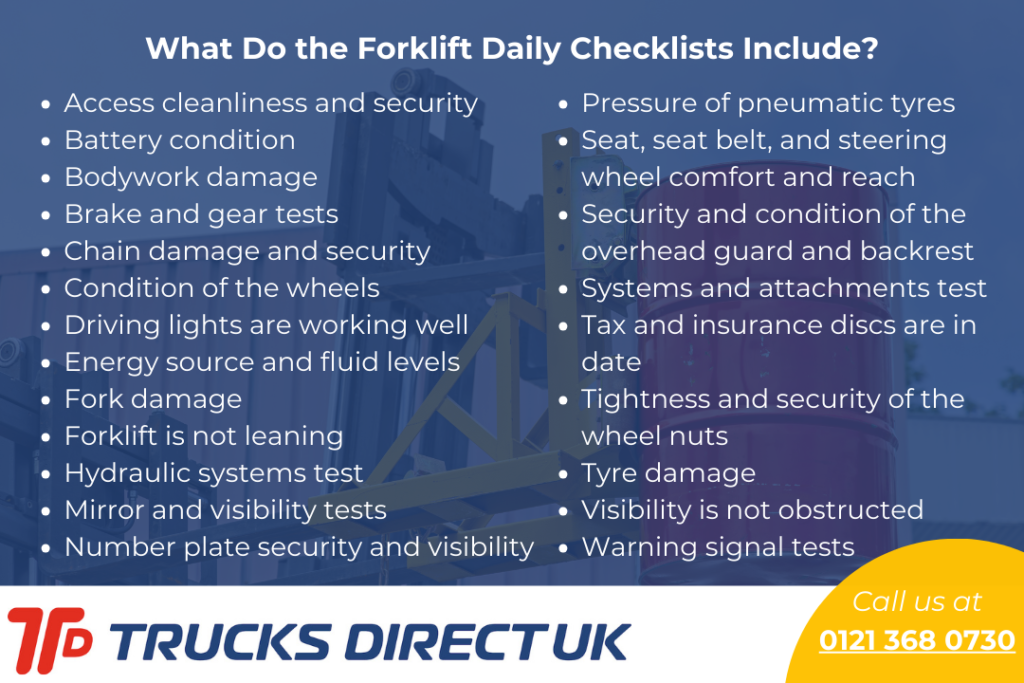

What Do the Forklift Daily Checklists Involve?

It’s ideal to check every aspect of your forklift before using it. Typically, your forklift daily checklist should include:

- Access cleanliness and security

- Battery condition

- Bodywork damage

- Brake and gear tests

- Chain damage and security

- Condition of the wheels

- Driving lights are working well

- Energy source and fluid levels

- Fork damage

- Forklift is not leaning

- Hydraulic systems test

- Mirror and visibility tests

- Number plate security and visibility

- Pressure of pneumatic tyres

- Seat, seat belt and steering wheel are comfortable and the controls are reachable

- Security and condition of the overhead guard and backrest

- Systems and attachments test

- Tax and insurance discs are in date

- Tightness and security of the wheel nuts

- Tyre damage

- Visibility is not obstructed

- Warning signal tests

While this list may seem exhaustive or daunting, it gets easier to understand with each check. And before each use, you can be sure your forklift is safe for your employees.

The Health and Safety Authority has an in-depth forklift check sheet that you can copy and use for all your future inspections. Alternatively, there are plenty of templates online if you wish to create your own or find a style that suits you.

Do I Need to Keep a Record?

Yes, you must keep a record of your forklift check sheets. Once it has been completed, store it in a filing cabinet or keep a digital copy in a folder with the other sheets. Make sure they’re dated and correct as they may be needed for the next inspection.

What Happens if I Find a Fault?

You must report any faults to your supervisor and ensure the forklift will not be used until fixed. If you use it while broken, your insurance may not cover any further damage or accidents.

Invest in Safe Forklifts with Trucks Direct

Now you know the importance of daily forklift checklists and how to ensure complete safety, we encourage you to investigate the ability of yours. If you find any defects, remember to report them to your supervisor and halt use until they’re fixed.

If you find yourself losing productivity and have a tight deadline, why not hire a forklift at Trucks Direct? Alternatively, invest in a brand new forklift to prevent costly repairs in the future.

We offer a range of both new and used forklifts, including electric, gas and diesel from leading manufacturers, such as JCB. Enquire today for a quick quote.